The product development cycle is a long and winding road, from development to eventual decline. However, this doesn’t mean that the process is devoid of excitement. During the designing and development phase, you conceptualize your product and think of its many features and benefits. Nothing is off-limits when you dream up your perfect product. As you tread through this process, you’ll eventually come across the building stage. This is when your product first materializes through a prototype.

Prototype Basics

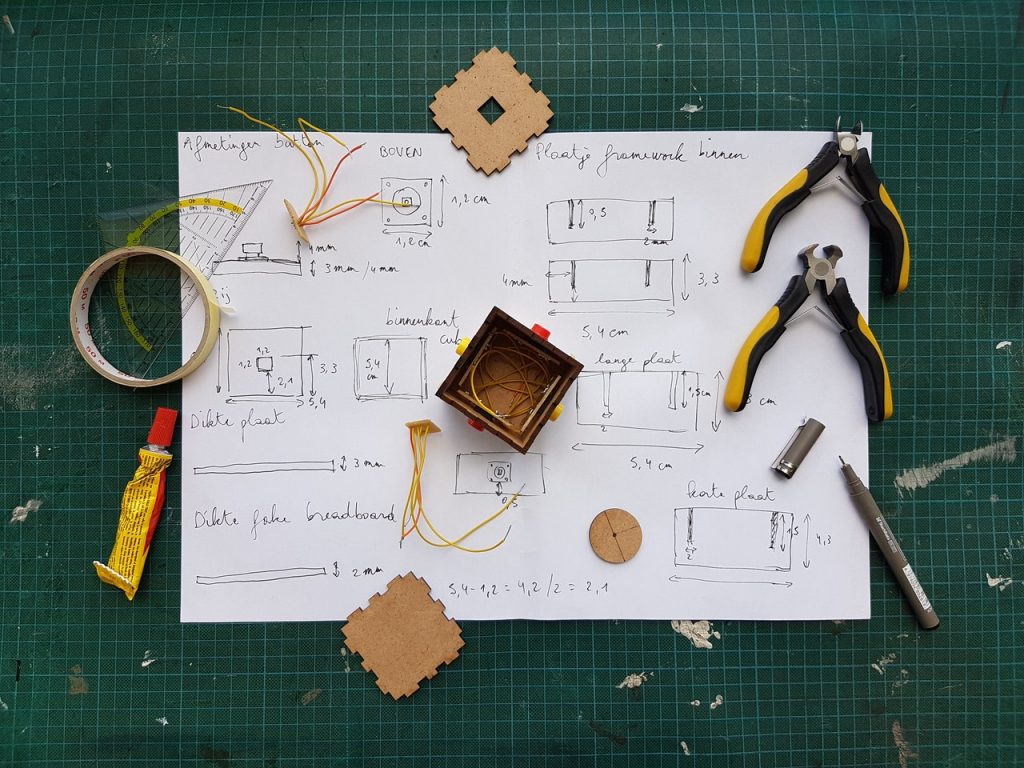

A prototype is an early sample or model of your product. You use it to test different processes and concepts. Here, you’ll find out if your product actually functions the way you intended it to. You’ll also see the probable flaws it has and how you can solve them. A prototype can be examined by your development team or even your customers. The more people that get their hands on your prototype, the faster you can get feedback about them.

Prototypes allow you to fail early. This way, you can find and solve problems before you get to the mass production stage. Because you only create a small batch of products, the risk of mistakes is low. You save time, money, and energy.

Here’s how to create a prototype that helps you perfect your product.

Determine the Kind of Prototype You’ll Create

There are a variety of prototypes you can build depending on what you want to test. Different prototype types include:

- Visual prototype — This focuses on aesthetics, as it has no functional parts just yet. A visual prototype’s focus is to figure out how you want to communicate the look of your product through its size, shape, color, texture, and more. You can create this using a 3D-modeling software like CAD or a physical model. ;

- Digital prototype — This involves creating a 3D model and a simulation of how your product works. It features not only the aesthetic parts of your product but also its moving components. Apart from seeing how your invention works through a simulation, it also stands as an extensive list of all the parts you’ll need for building your product.

- Functional prototype — Also known as a proof-of-concept prototype, this involves creating a model that proves that your invention works as intended. You don’t focus as much on how it looks. You’ll create a lot of these as you revise your design.

- Presentation prototype — This merges your functional and visual prototype to create a model that’s close to your final product. Your build should exhibit the full functionality of your product while also replicating the look and feel of your visual prototype.

Secure Your Prototype

Your prototype shouldn’t just show that your product is functionally and aesthetically feasible, it should also pass performance and safety standards in your industry. Send your designs to inspectors first before proceeding to create physical copies of them. ; You should also make sure your prototype and its design are fully protected. Register a patent for your design or have your manufacturing partners sign a confidentiality agreement to ensure your product doesn’t get leaked to the public and possible competitors.

Get the Necessary Funding

Even if you’re not making the mass production version of your invention just yet, you still need to pay for materials and labor costs to make prototypes. If you don’t have enough money saved up for building your prototype, you can get funding from a bank loan, grants from your industry’s charities, investors, or even a business partner.

Get it Made

Once you’ve figured out the type of prototype you’ll make and you’ve secured its design and funding, it’s time to have it made. Find a prototyping specialist and manufacturer who can fulfill your invention’s requirements. For example, your prototype may need an industry-grade cutting machine because some of its parts need to be made with pinpoint precision in order to work correctly.

Make sure the company has experience working with companies in your industry, too. If you’re making accessories for bobber motorcycle, choose a firm that specializes in automotive parts. This way, you can be confident that they have the expertise, processes, and equipment to handle your request. ; ;

Developing a product is a tedious, yet rewarding process. One of the most exciting phases of it is finally getting a glimpse of your invention through a prototype. But even that isn’t as easy as it seems. With a clear understanding of the type of prototype you’ll create, the necessary protections and patents, and a manufacturer that understands your requirements, you’ll have a prototype that gives you all the information you need to create a mass production-ready product. ;